FastCast Ceramics

Passionate about ceramics.

Your partner for innovative technical ceramics.

FastCast Ceramics.

Ceramics is our passion. It enables the manufacture of high-tech products as well as products for everyday life. Due to their special characteristics, technical ceramics are used in numerous industries such as mechanical and plant engineering or medical technology. FastCast Ceramics is your specialist for open-pore technical ceramics.

By combining innovative ideas and new technological approaches, we at FastCast Ceramics have succeeded in developing a sustainable slip agent for the production of high-performance ceramics. With our flexibly applicable high-performance ceramics, we want to make a contribution to enabling the efficient and economical production of high-tech products in the future as well – on an ecological and sustainable basis.

Applications & solutions for investment casting.

Investment casters are faced with numerous challenges. In addition to the production of geometrically complex and demanding geometries, high standards of surface finish must also be achieved. Another challenge is the production speed at which the castings are produced: a limiting factor here is the production of the ceramic shells. Using innovative ideas and technologies, FastCast Ceramics has succeeded in reducing the production time of ceramic shells for investment casting. In addition, the solution is also used to repair cracked shells that have already been manufactured.

Challenges in investment casting

The investment casting process is one of the oldest and most complex casting processes. The complex and filigree components are first produced as wax parts in the injection molding process. These are then glued together to form a wax tree, dipped in a ceramic slip, sanded and dried. This triad currently has to be repeated between 8 and 13 times to produce a sufficiently thick shell. This process is time-consuming, so it currently takes up to 10 full days until the mold shells are ready for casting.

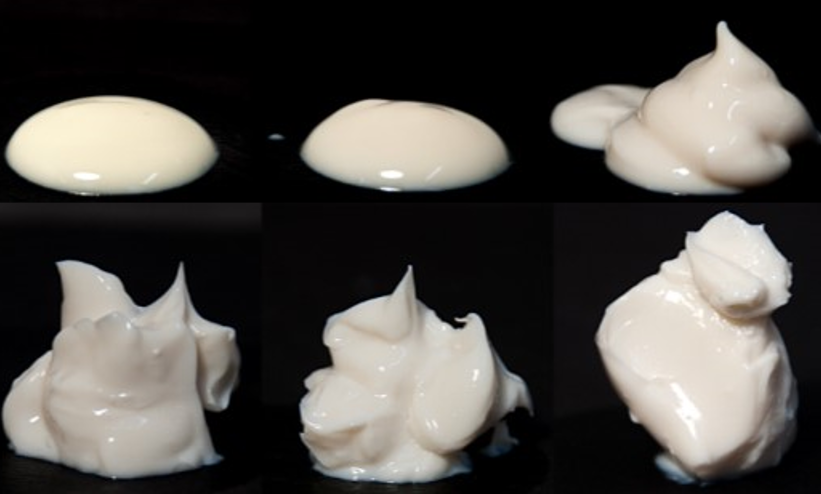

Innovation meets solution

The FastCast Ceramics ceramic slurry significantly simplifies and accelerates this process in the future. Thanks to the fast and crack-free drying of the ceramic slurry, a thicker layer can be applied per dipping process. In addition, the process step of sanding becomes obsolete. This is because the ceramic from FastCast Ceramics has sufficiently high strength for low-defect dewaxing and can be easily separated from the casting after casting. This reduces the time required for mold production using FastCast Ceramics slurry to two to three days.

The FastCast Ceramics solution is a drop-in technology, which is delivered ready-mixed to our customers. This allows a fast and uncomplicated application in existing production lines without the need for retooling.

Benefits for our customers

The use of FastCast ceramic slurry results in numerous advantages in the investment casting process, which uncover great potential for investment casters. On the one hand, the acceleration of the process leads to an increase in capacity. On the other hand, the use of sanding machines is no longer necessary, because the strength of the investment casting shell is achieved by using FastCast Ceramic Slurry even without the sanding step. FastCast Ceramics delivers the slurry premixed and it can be used directly. A time-consuming mixing on site is no longer necessary and investment casters can concentrate on their core competence, casting. Furthermore, the high long-term stability of the slurry allows problem-free storage. Another advantage resulting from the elimination of sanding is the first-time possibility of recycling chipped ceramic shells.

Ceramic glue for investment casting

The manufacture of various products using the investment casting process is complex, demanding and takes a lot of time. If conventional ceramics are used for shell production, it can take up to 10 days from the first dipping process to the finished production of the component. It is not uncommon for it to be technically necessary to drill holes in the shells before the lost wax is melted out in order to prevent cracks from forming. If cracks nevertheless form in the mold shells after the wax has been melted out, this is not only annoying but also causes economic damage, because the cracked shells are no longer available for further process steps.

FastCast solutions

The FastCast Slurry for shell repairing allows a material-independent, quick and effective repair of drilled or cracked shells. For this purpose, the ready-mixed, highly porous slurry is applied to the cracks, dried and sintered. The shells are then available again for further process steps, thus minimizing scrap. FastCast’s investment casting adhesive can be combined with all conventional materials for shell production and can thus be used flexibly.

Benefits for our customers

The FastCast Ceramics investment casting adhesive enables a low-effort and significant reduction of the scrap rate in investment casting. The shells repaired in this way are available again for the further investment casting process and there is no economic damage.

Solutions for your slurry and paste development.

Your partner for advanced suspension technology

Welcome to FastCast Ceramics, your expert for development services in the field of suspensions. We are specialized in the adjustment and optimization of rheological properties. Our capabilities include the precise adjustment of yield stress and viscosity to ensure that our slurries and pastes meet your exact requirements.

We are particularly proud of the crack-free drying of thick layers. To achieve this, we rely on new technologies and manage without the generous use of binders. The porosity of the drying layer can be adjusted between 15% and 75% as required. Our coatings are completely open-porous, meaning that the entire pore volume is permeable.

Our technologies make us your ideal partner for product development in demanding applications where workability and properties after drying are crucial. Our solutions are always tailored specifically to your needs. A particular focus of our work is the development of water-based systems with a minimal proportion of organic substances. We also master this challenge by using our advanced techniques and the results of decades of research. We are your partner in the development of environmentally friendly yet high-performance suspensions.

Discover how FastCast Ceramics can revolutionize your product development. Contact us today to find out more about our customized suspensions and how they can benefit your business.

High-performance technical ceramics from FastCast Ceramics.

Technical Characteristics

Ceramic materials have numerous positive technical characteristics. These include high chemical and thermal resistance. FastCast Ceramics are also characterized by exceptionally high (open) porosity with simultaneous high mechanical strength. Ceramics from FastCast Ceramics have pore sizes between 0.2 µm and 50 µm with a porosity of 35 to 75%. Since the principle of capillary suspension works almost independently of the material, we can work with almost all ceramic materials. In addition, we are also flexible in the shaping method.

This results in numerous new areas of application or improvements in processes in which ceramics are already used. In addition to the products currently under development, we are always on the lookout for new areas of application and development partners.

Ecological

Ecology and economy are in harmony at FastCast Ceramics. Already at the beginning of the product development, ecological aspects have a high priority. We pay attention to the use of environmentally friendly sustainable raw materials and think recycling from the beginning. By using new technologies, we aim to develop environmentally friendly products that provide our customers with added economic value. Following this principle, our material system almost completely does without organics in production.

Economic efficiency

Efficiency and economy play a central role in processes and the use of resources for every company. The technical ceramics from FastCast Ceramics bring numerous advantages. These include, for example, the use of sustainable raw materials, which generate a high individual benefit for our customers. The added value for the customer is already a central driver during product development. This is also reflected in value-based pricing. In partnership with our customers, we determine the specific added value that is created for them through the use of our ceramics. This approach guarantees that our customers become more profitable and have more resources available to concentrate on their core competencies.

Innovative

Our goal is to bring forth innovations in the field of ceramics production for various industries and to develop them into usable products. To this end, we make use of the latest findings and technologies from science. With this approach, we have succeeded in producing an innovative ceramic almost free of organic material on the basis of the water-based capillary suspension.

The Founder Team.

As a team, we at FastCast Ceramics have made it our goal to continuously develop our innovative and environmentally friendly ceramic technology, to distribute it worldwide and to be a reliable partner for our customers. In addition to our high degree of innovative spirit, we are guided on this path by our values and principles. These shape our actions and are based on humanity, fairness and our high level of environmental awareness. These values are expressed in respectful interaction and open communication, both internally and externally.

Centrally anchored in our actions is the passion for ceramics and the vision to further advance the manufacture of high-tech products with the help of technical ceramics through technological innovations. We achieve this vision thanks to our broadly based team, consisting of Moritz, David and Wolf. In addition, numerous student assistants and graduates support us in realizing our vision.

Dr. David Menne

Product development is mainly in the hands of David. His purposeful, calm and determined nature drives FastCast’s product solutions forward every day. After studying mechanical engineering at RWTH Aachen University, he started his doctorate at the Karlsruhe Institute of Technology (KIT) at the end of 2017. In his doctoral thesis, he deals with the development of soil moisture sensors. David likes to spend his free time outside hiking, climbing or cycling.

“Taking the next step on the basis of our research work on porous ceramics and developing innovative as well as sustainable products that generate real added value – that’s just what I feel like doing.”

Wolf G. Wedel

Wolf is responsible for strategy and finance at FastCast. Through his entrepreneurial and economic vision, he always has the vision of FastCast in mind. After studying mechanical engineering at RWTH Aachen University, he was able to further develop his analytical skills as a research assistant at the Technical University of Munich. There he is currently writing his doctoral thesis. The family man likes to spend his free time jogging, a good book or his family and friends.

“I’m excited about generating value hand-in-hand with our customers as partners, based on insights from science and creativity, and thereby creating added value for our society.”

Dr. Moritz Weiß

Moritz is not only Managing Director at FastCast, but also takes care of product development. After studying chemical engineering at the Karlsruhe Institute of Technology (KIT), he received his doctorate from KU Leuven. Subsequently, he worked as a post-doc at KIT. It was there that the idea for FastCast was born. Moritz can hardly walk past a volleyball court without playing on it. He also likes to spend his free time in good company with friends.

“At FastCast I work in a super team and can actively accompany the transfer from our research to innovation. Creating sustainable and efficient products from our research work motivates me.”

Student assistants and final year students

Our team is completed by our student assistants and graduates, who actively support us in the realization of our version.

Dilara

She drives product development for the investment casting ceramic slip.

Alessandro

He is driving product development for the investment casting ceramic slip.

Nando

He is driving product development for the investment casting ceramic slip.

Alexander

He is assisting FastCast in the development of the ceramic slurry for investment casting.

Sahr

In her bachelor thesis, she is researching the topic of investment casting slurry.

Daniela

She drives CIM product development for FastCast.

Jan

His bachelor thesis revolves around the topic of “recycling ceramics”.

Robin

Robin helps developing ceramic 3D printing for FastCast.

Philipp

He is working on his master’s thesis on ceramic 3D printing from capillary suspension.